Products

Machining Center

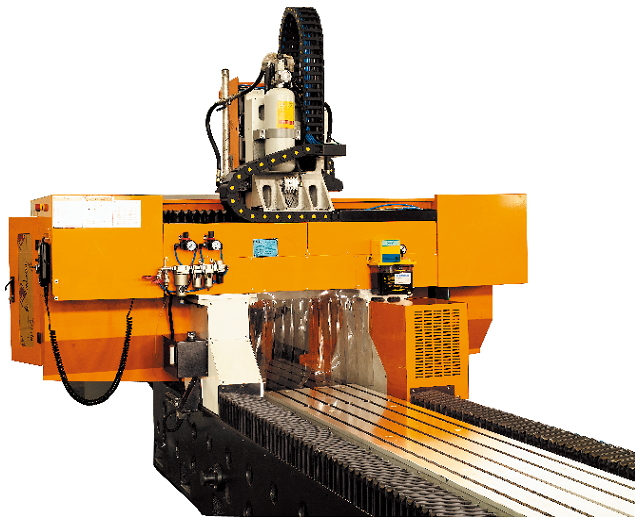

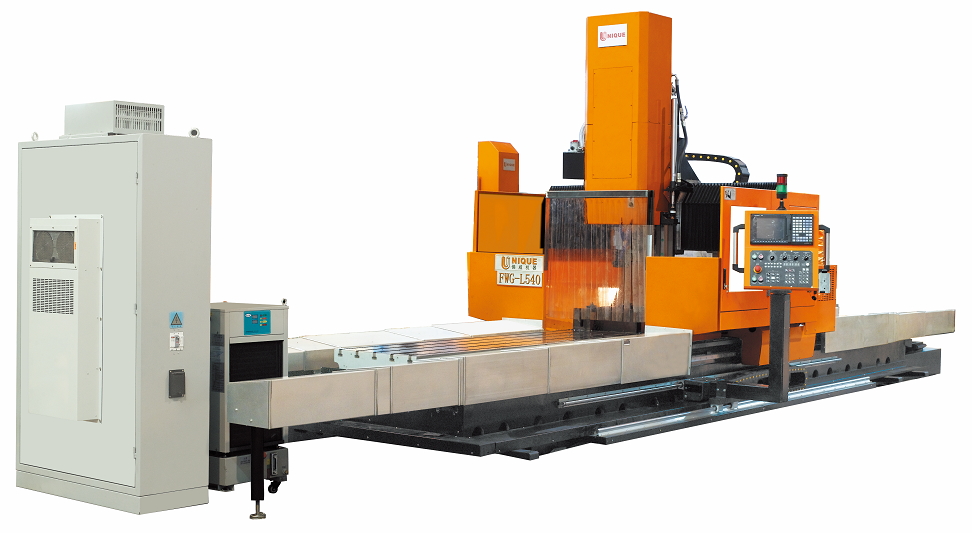

| Longmen processing center for aluminum profile extrusion die |

| Product Type: |

Brief Description: |

型材動柱(zhu)式龍門加工中心(xin)

Section Moving Column Machining Center In Longmen

FWG-L645AI / FWG-L665AI /FWG-L1280

產品參數

The Product Parameters

|

項目 |

FWG-L645AI |

FWG-L665AI |

FWG-L1280 |

|

|

行 |

X軸行程mm |

4000 |

8000 |

|

|

Y軸(zhou)行(xing)程mm |

850 |

1600 |

||

|

Z軸行程mm |

500 |

500 |

||

|

龍門寬度/高(gao)度mm |

880X600 |

1500X1850 |

||

|

主 |

主軸(zhou)規格(ge) |

BT-50 |

BT-50 |

|

|

主軸最高轉速rpm |

8000 |

8000 |

||

|

主軸端面至工作臺面距離mm |

170~670 |

300~800 |

||

|

刀 |

刀(dao)庫形式 |

排式刀(dao)庫/鏈式刀(dao)庫 |

排式(shi)(shi)刀庫/鏈式(shi)(shi)刀庫 |

|

|

刀(dao)庫容(rong)量 |

10把(ba)/40把(ba) |

10把/40把 |

||

|

移動 |

X軸(zhou)快速(su)移(yi)動m/min |

20 |

16 |

|

|

Y軸(zhou)快(kuai)速移動m/min |

20 |

16 |

||

|

Z軸快速移動m/min |

20 |

16 |

||

|

工 |

工作臺尺寸mm |

650X4500 |

650X6500 |

1200X8000 |

|

工作臺最大承(cheng)重kg |

4000 |

6000 |

8000 |

|

|

動力 |

主軸電機功率kw |

11 |

18.5 |

|

|

主軸配齒輪箱 |

配德(de)國ZF120雙速齒輪箱 |

|||

|

X、Z軸電機功率 |

3/3kw |

4.5/4.5kw |

||

|

X軸雙驅(X軸配減速機) |

3.5kw X 2 |

2.2kw X 2 |

||

|

精 |

X軸定位精(jing)度mm |

?0.02 |

?0.04 |

|

|

X軸重復定位精度mm |

?0.01 |

?0.02 |

||

|

X、Z軸定位精度mm |

?0.012 |

?0.012 |

||

|

X、Z軸重復定位精度mm |

?0.008 |

?0.008 |

||

|

潤滑 |

潤滑系(xi)統 |

集中(zhong)潤滑 |

||

|

冷卻系統 |

切(qie)削液冷(leng)卻 |

|||

|

排屑(xie) |

雙螺旋+鏈板式排屑 |

|||

|

機床 |

機床(chuang)外形尺寸(長X高X寬(kuan))mm |

8000X2000X2500 |

10000X2000X2500 |

12000X2500X2800 |

|

機床總重T |

12 |

15 |

25 |

|

|

機床輸(shu)入電(dian)壓功率 |

380V/25KVA |

|||

|

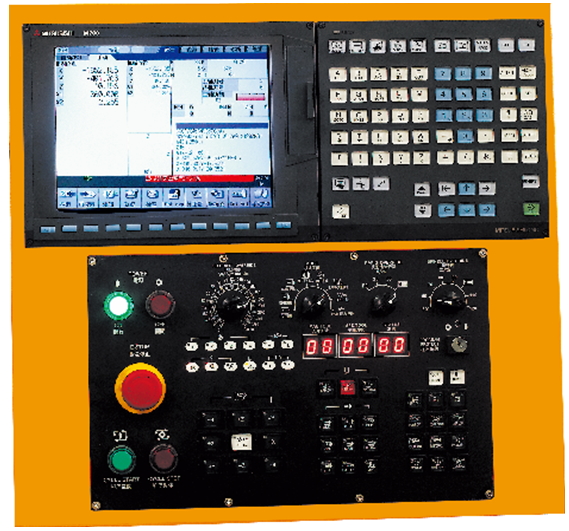

數控系統 |

三菱/西(xi)門子/發(fa)那科 |

|||

數控動柱式(shi)龍門加工中心

CNC Movable Column Machining Center In Longmen

FWG-L645AI / FWG-L665AI /FWG-L1280

產品特點

Product Features

|

|

|